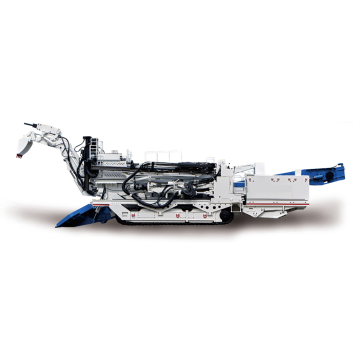

Drilling Loading Bolting Machine for Coal Mine

Drilling Loading Bolting Machine for Coal Mine

| Payment Type: | L/C,T/T |

|---|---|

| Terms of Trade: | FOB,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

| Packaging: | Wooden Cases |

|---|---|

| Productivity: | 500 /Year |

| Brand: | NHG |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | PRC |

| Supply Ability: | 500 |

| Port: | DALIAN SEAPORT,TIANJIN SEAPORT,SHANGHAI SEAPORT |

Basic Info

Model No.: CMZY4-200/35

Click on the follow link to find out more information: https://www.nhgtunnel.com/drill-loader-bolter-integrated-equipment/

Company Info

- Company Name: NORTH HEAVY GRYPS EQUIPMENT AND ENGINEERING CO.,LTD

- Representative: JU KUNPENG

- Product/Service: Mining Roadheaders , Tunneling Roadheaders , Drilling Jumbos , Drilling Rigs , Bolter Machines , Continuous Miners

- Capital (Million US $): 20,000,000 RMB

- Year Established: 2013

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 81% - 90%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: above 20

- No. of R&D Staff: 91 -100 People

- No. of QC Staff: 91 -100 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: 5-1 Tianci Street,Hunnan District, Shenyang,110000, PRC

- Contact Person: Ms. Lily Zhang

- Tel: 86-13998186634

Premium Related Products

Other Products

Hot Products

Servo Feedback Motor Cable MOTORFLEX-X EMV 1/1 Triple Shielded Low Capacitance +80 C/+176 F 600 V PUR Flexible VFD Moto 4 core0.66 / 1.14KV Coal Cutter Semi-conducting Screened Monitoring Braided Flexible Cable

Elastomer (Rubber) Insulated CableKVV32 steel wire armored cable SWA control cable2/0 AWG green ground PVC stranded copper cableXLPE Cable 500mcm Copper Cables XHHW-2 Wire AWG2 Core 0.71mm Drop wire outdoor telephone cable factory3 Core AL XLPE Insulated 300mm 15kV 25kV Underground Cable4 sq mm Aluminum Core PVC Insulated Wire 16mm2 Single Core CableBC 2 x 20 Gauge 0.8mm Drop Wire Outdoor Telephone Cable6.35/11kV Screened ABC Aerial Bundled CablesAluminum Conductor Aerial Concentric Cable KS 1022:2015 standard2/0 SGT SAE J1127 105 C PVC Insulation Automotive battery cable

Automotive Battery Cable

SGT Automotive Battery CableBare ACSR Cable Aluminum Conductor 120mm2AAsXSn CCX-AL3 WK 12/20 (24) kV Cable XLPE Insulated Medium Voltage Overhead LineSingle core PVC 6181XY Cable Double Insulated Surface WireDouble insulated cable 6181Y for building wiring